Capabilities

The automatic spray painting machine is used to paint furniture parts, doors, panels and other parts of the suitable dimensions:

Length (max/min), mm – 4,000 / 300

Width (max/min), mm – 1,200 / 5

Height (max/min), mm – 80 / 5

Part weight, max – 75 kg.

DataSheet

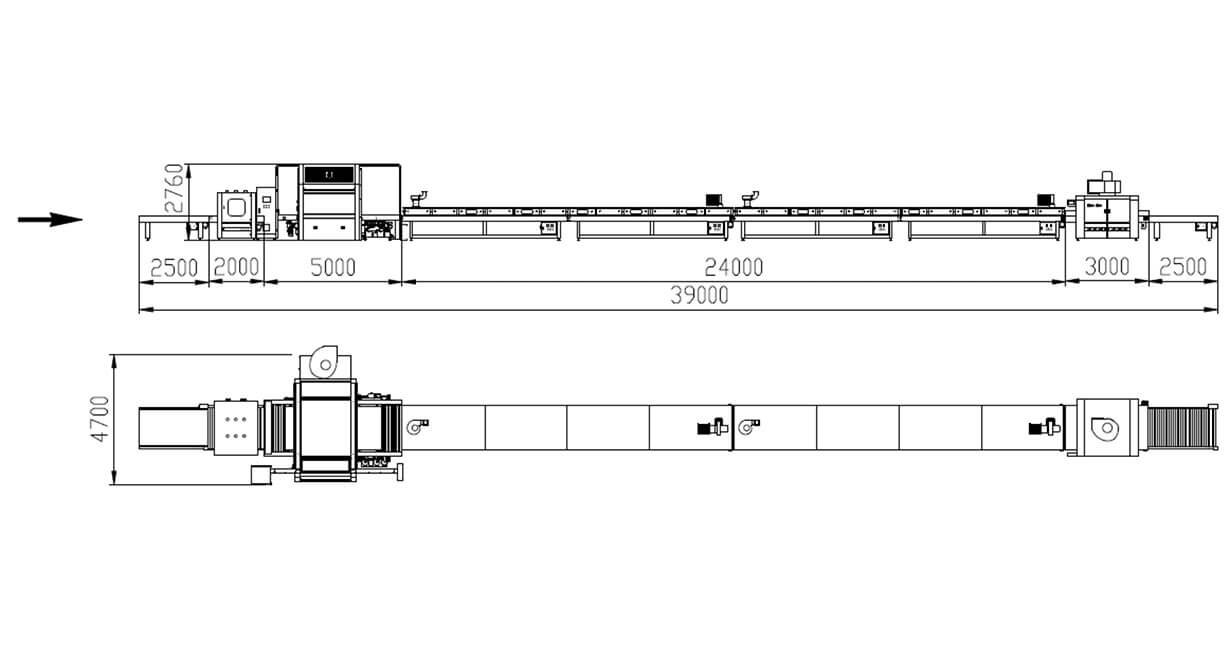

Product dimensions

| Min/max length of the painted product | 300/4,000 mm |

|---|---|

| Min/max width of the painted product | 5/1,200 mm |

| Min/max height of the painted product | 5/80 mm |

| Part weight (max) | 75 kg |

Equipment dimensions

| Equipment dimensions (L x W x H) | 5.0 x 4.7 x 2.8 m |

|---|---|

| Equipment weight | ~ 2,500 kg |

Power

| Supply ventilation power | 3.0 kW |

|---|---|

| Exhaust fan power | 3.0 kW |

| Air exchange | 9,800 m³/h |

| Water pump power | 2.2 kW |

| Servo motor | 4.0 kW |

| Total power of the paint booth | 15 kW |

Basic description

| Maximum number of spray guns | 8 pcs. |

|---|---|

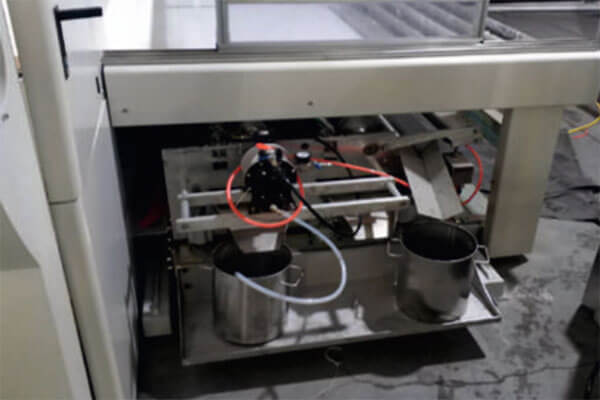

| Part feeding | a belt conveyor with a smooth stepless speed control |

| Feed speed | 1-5 m/min. Adjustable during operation. The current speed is shown on the digital display |

| The feed belt | is antistatic, highly resistant to mechanical and chemical exposure |

| Suitable for spraying | of all kinds of paints (PU, PE, UV, NC, water-based materials, etc.) |

Climatic conditions

| Outside temperature, °С | 10-30 |

|---|---|

| Relative humidity,% | 40-70 |

| Sun rays | Sun rays |

Components

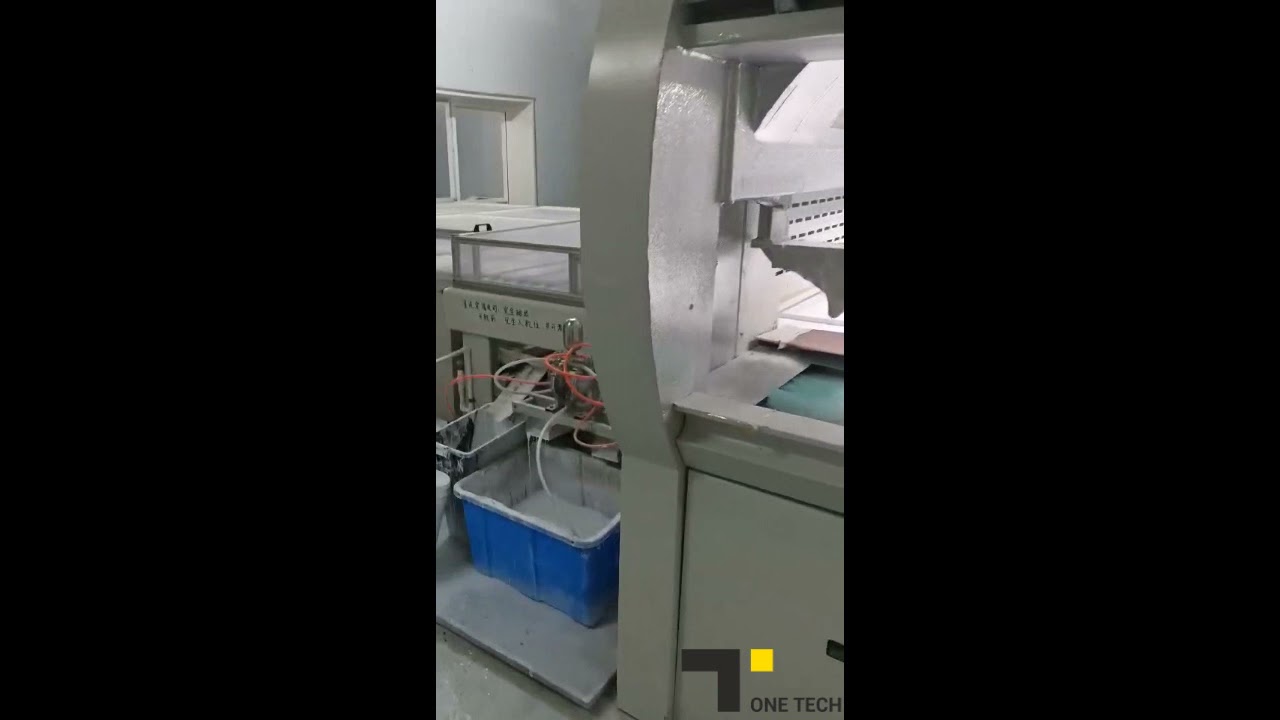

| Spray painting machine body | with a supply and exhaust ventilation system, paintwork material recuperation and a hydraulic filter, stainless steel, China |

|---|---|

| Schneider electrical components | Schneider, France |

| PLC, frequency controller | Matsushita, Japan |

| pneumatic system | Yadeke, Taiwan |

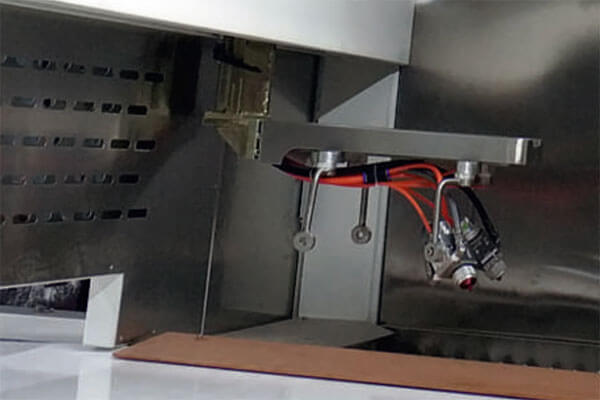

| Auto paint spray gun | DURR, ECO GUN AA Auto, 4 pcs., Germany |

| Piston pump | DURR, ECO PUMP VP, 1 pc., Germany |

Technical features

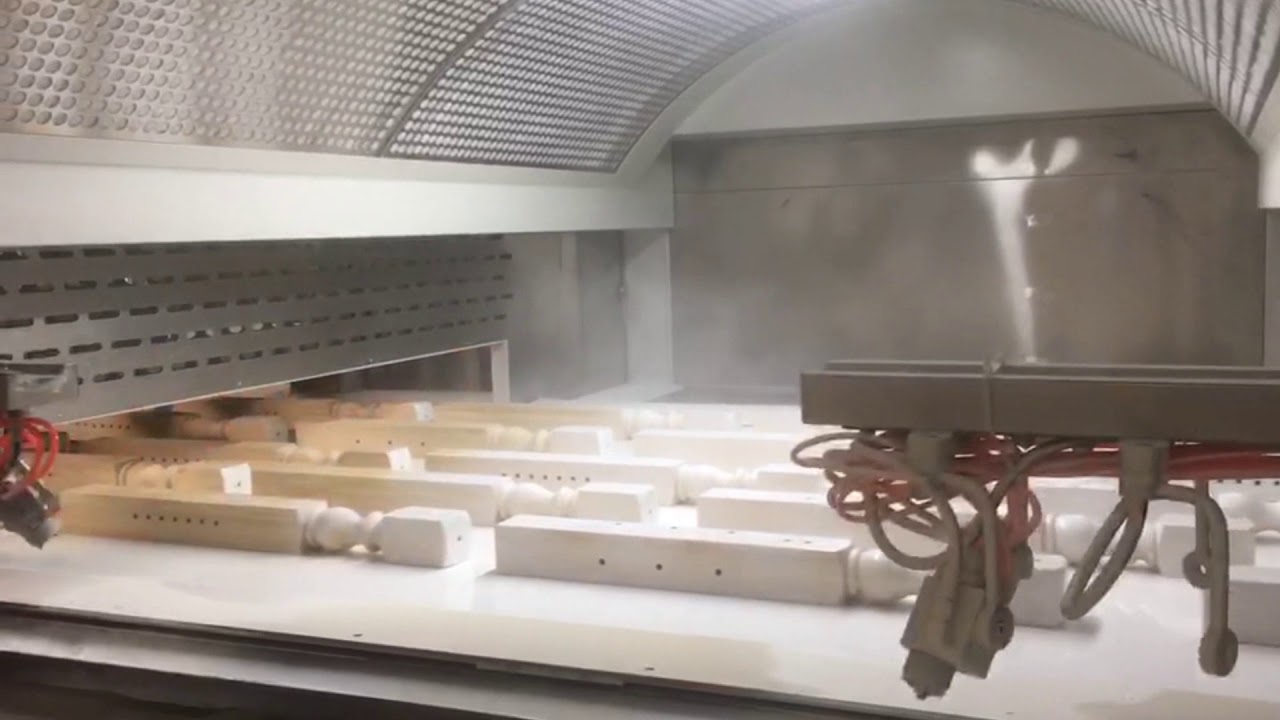

OneTech UV painting line

Complete enamel coating.

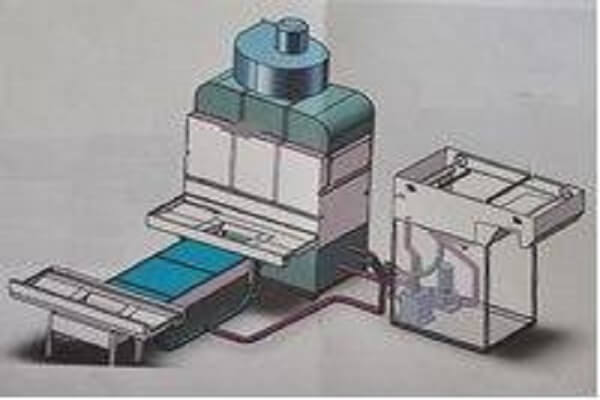

The automatic painting line consists of the following equipment:

+ Belt conveyor

+ Automatic spray painting machine

+ Laminar flow tunnel

+ UV dryer

+ Roller conveyor

OneTech UV painting line

Transparent varnish coating.

The painting line consists of:

+ Belt conveyor

+ Automatic spray painting machine

+ Laminar flow tunnel

+ UV dryer

+ Roller conveyor

Example of door painting with the use of OneTech line

A line for painting of furniture parts, panels, doors. For application of solvent or water-based paintwork materials.

Example of painting of decorative furniture balusters

using ONE TECH automatic machine

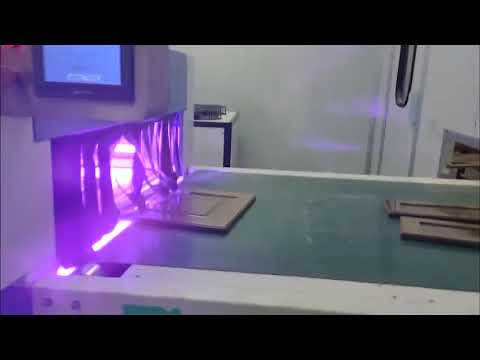

Control panel of the ONETECH universal painting machine

We will program the ONETECH in your comfortable language

Painting with nitro enamel

Example of an automatic paint line for painting with nitro enamel

Painting line for high-gloss fronds

Automatic painting and drying of high-gloss fronts

Assemble One Tech automatic Assemble One Tech automatic UV painting line

Advantagesof ONE TECH equipment

Efficiency

Increased painting efficiency of your product (furniture parts, doors, panels or other products)

Saving

Saving of paintwork materials

Speed

Continuous application and flexible spray gun setting

Process automation

Consistently high quality of the finished product compared to manual painting

Quality

German spray technology

Labour automation

Only two employees are necessary for a simple operation – loading and unloading of the spray painting machine